What is a Fanuc alarm 8, 9, or A?

Fanuc servo alarms 8, 9, or A are high current alarms triggered by the CNC system when it detects an abnormal current level in the servo amplifier. Specifically, a Fanuc 414 servo alarm is displayed when one or more amplifiers report this high current condition.

These alarms typically signal a critical issue with the drive system, and identifying the exact cause requires a process of elimination. Possible sources of the alarm include:

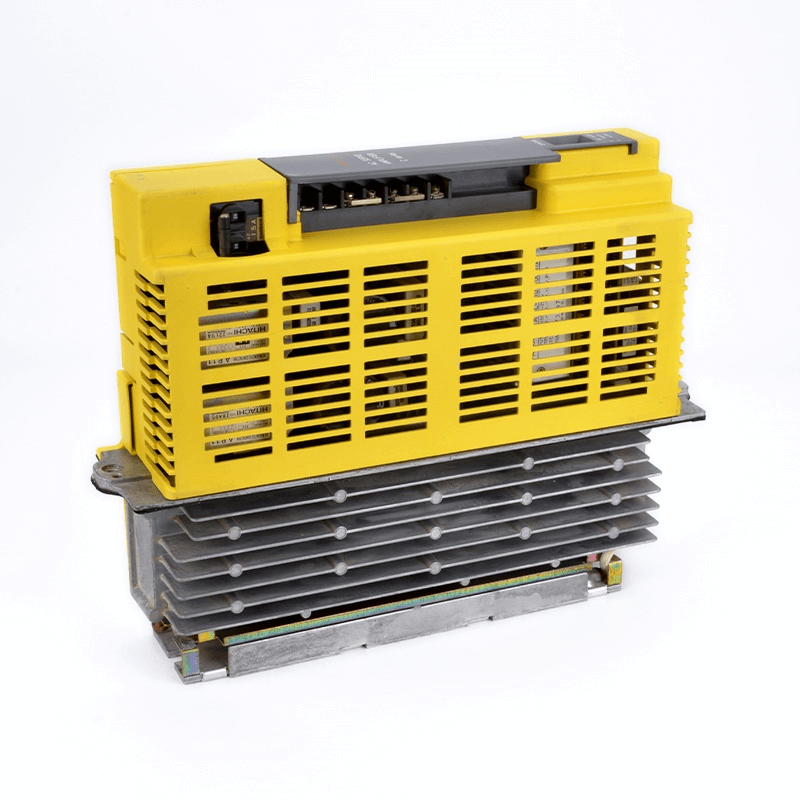

- Faulty servo drives or servo amplifiers

- Damaged power modules

- Worn-out servo motors

- Defective or shorted motor power cables

In some cases, Fanuc Alarm 8, 9, or A may indicate a short to ground, which causes excessive current to flow through the power module inside the amplifier. If unresolved, this can lead to permanent damage to the module or the entire unit.

If you’re experiencing a Fanuc high current alarm, it’s essential to diagnose the entire drive system, including cables and motors, before replacing parts. Early intervention can prevent costlier repairs and extended machine downtime.

저희에게 연락하십시오Here is the Fanuc alarm 8, 9, or A message

- Alarm 8 / b = First Axis = L channel (on single, dual or triple axis drive).

- Alarm 9 / c = Second axis = M channel (only on dual or triple axis drive).

- Alarm A / d = Third axis = N channel (only on triple axis drive).

How to Diagnose a Fanuc alarm 8, 9, or A?

Diagnosing Fanuc servo alarms 8, 9, or A requires a step-by-step electrical inspection to determine whether the fault lies in the amplifier, motor, feedback system, or power cable. Follow the steps below to accurately identify the cause:

Step 1: Access the Electronics Cabinet

With the machine powered on (WARNING: High voltage inside), open the electronics cabinet to inspect the servo amplifiers.

Step 2: Identify the Faulty Amplifier

Look at the seven-segment display on each amplifier unit. One of them should be showing Alarm 8, 9, or A, indicating the high current fault.

Step 3: Understand Alarm Meaning

Although Alarms 8, 9, and A represent the same error (high current), each one corresponds to a specific amplifier axis where the fault occurs.

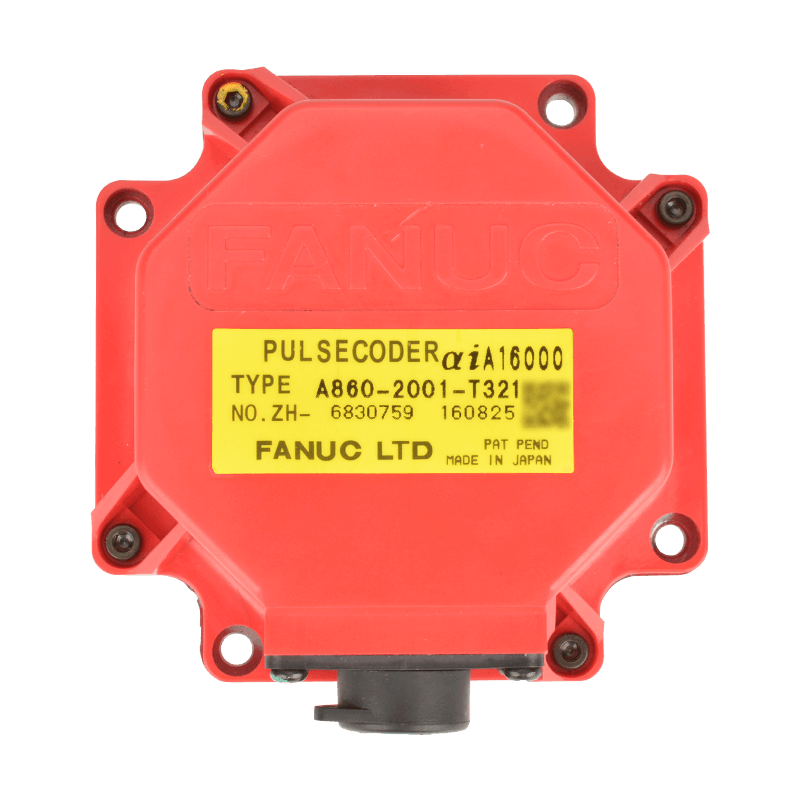

Step 4: Isolate the Feedback System

Turn on the main machine breaker, but keep the CNC control powered off.

If the alarm appears while the CNC is off, disconnect the feedback connector from the indicated amplifier axis, then power on the breaker again.

- If no alarm appears, the issue may lie in the pulse coder or feedback cable.

- If the alarm still appears, the amplifier is likely faulty and may require replacement.

If the alarm only shows when the CNC is turned on, proceed to check the motor, drive, and power cables.

Step 5: Disconnect the Motor Leads

Remove the four motor power leads connected to the bottom of the amplifier.

Step 6: Power the CNC System

Turn on the CNC. Make sure to release the emergency stop condition.

For vertical axis motors, prop up the axis before releasing the brake—otherwise, it may fall due to lack of motor holding power.

Step 7: Check for Alarm

If Alarm 8, 9, or A still appears, the amplifier is faulty.

If the alarm does not appear, continue testing the motor and power cables.

Step 8: Test the Motor with an Ohmmeter

Use a digital ohmmeter to check resistance:

- Leg-to-leg readings: Should be low but consistent across all three legs.

- Leg-to-ground readings: Should be open (OL) on each leg.

Step 9: Test for Ground Fault with a Megger

Use a megohmmeter (megger) at 1000V setting:

- Check each leg to ground.

- Readings should show infinity or at least 500 megaohms.

- If a short exists, the fault may lie in the motor power cable or the motor’s terminal box.

CIT 서비스

If your CNC displays a Fanuc 8, 9, or A, CIT can deliver fast, reliable repair services for your faulty spindle drive or you can purchase a newly refurbished unit.

창고에는 100,000개 이상의 재고가 있으며, 국내외 주문량이 많아 매일 업데이트됩니다. 우리는 항상 당신이 우리 회사를 방문하고 우리에 대해 더 많이 아는 것을 환영합니다.

저희에게 연락하십시오