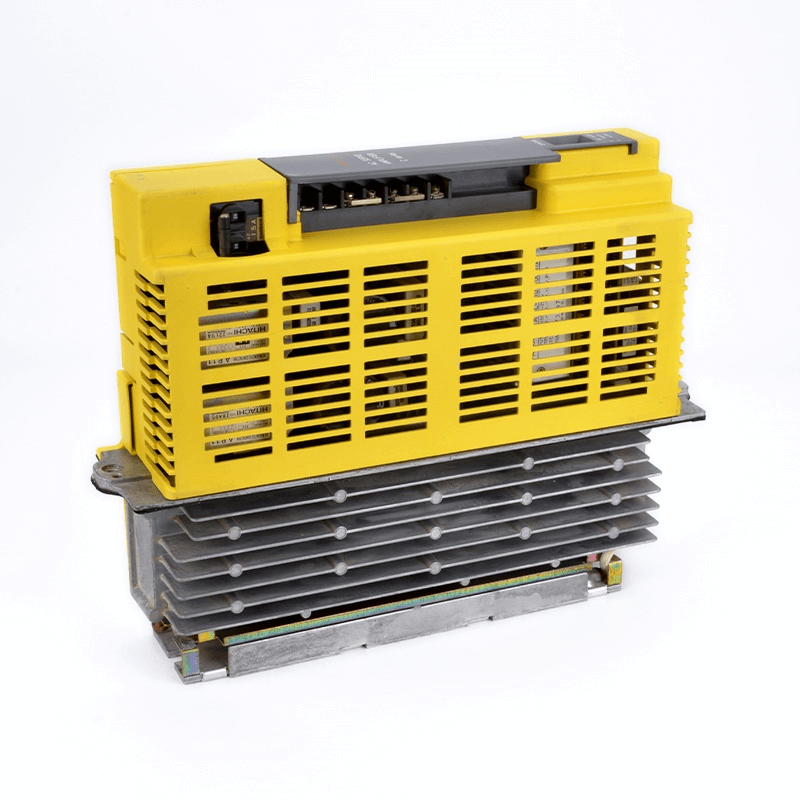

When a Fanuc servo motor begins to show signs of degradation—such as erratic motion, overheating, or loss of positioning accuracy—it may not be necessary to invest in a brand-new unit. In many cases, refurbishing a Fanuc servo motor can be a highly cost-effective and reliable solution. By restoring a used or damaged motor to near-original OEM specifications, companies can extend machine life, reduce downtime, and save significantly on replacement costs.

The Fanuc Servo Motor Refurbishment Process

A professional refurbishment follows a structured sequence designed to restore full functionality, mechanical integrity, and electrical accuracy. Here’s a general overview of how Fanuc servo motors are professionally rebuilt:

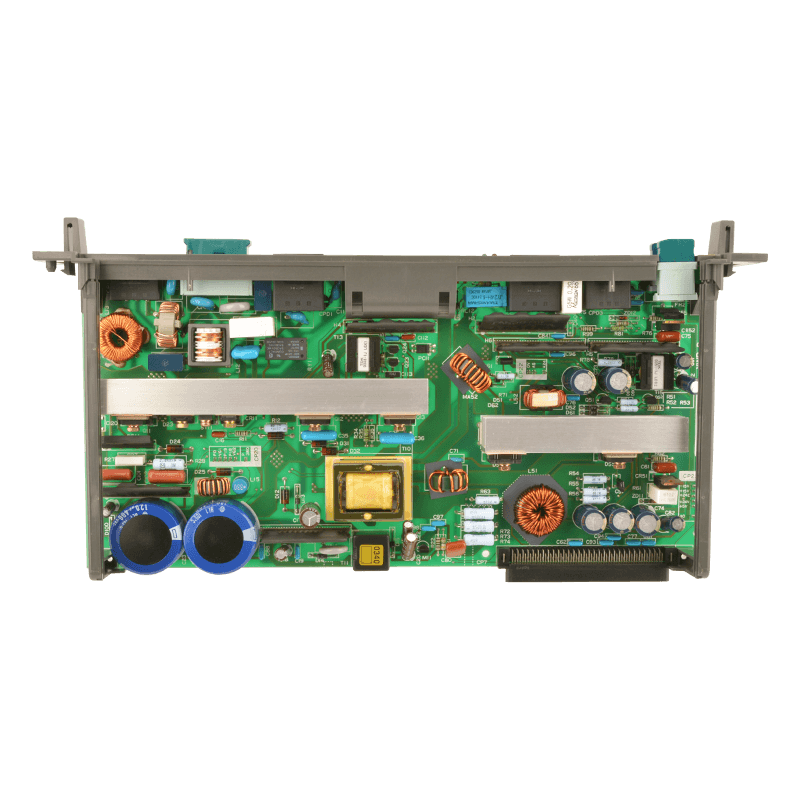

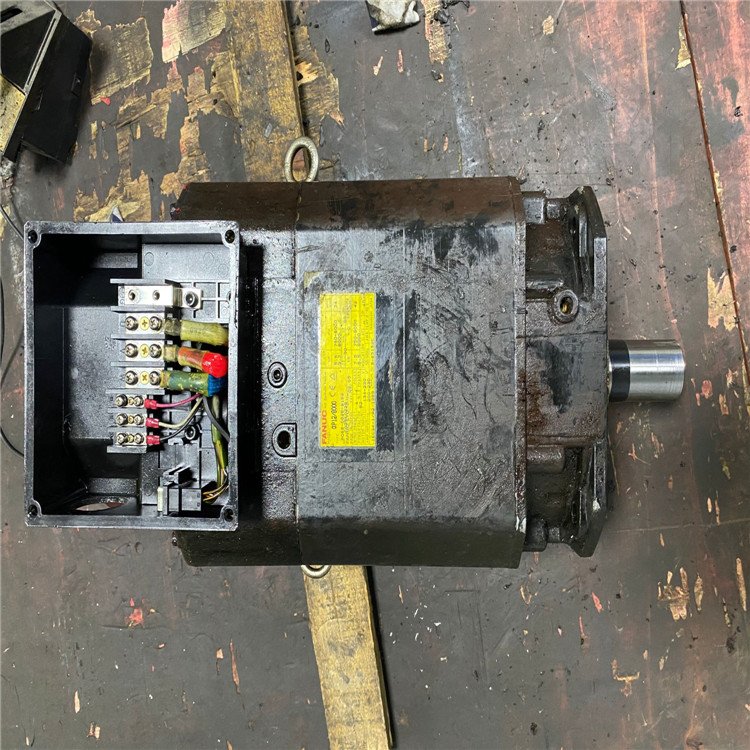

- Disassembly & Initial Inspection – The motor is carefully dismantled, and all components are visually and electrically inspected for wear, corrosion, and failure points.

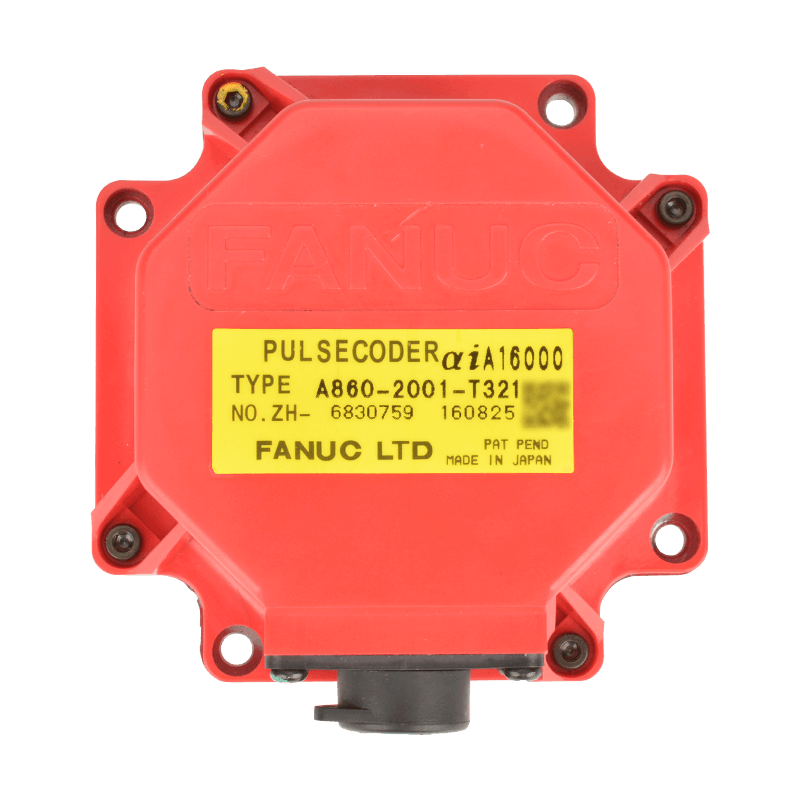

- Cleaning & Component Testing – Internal and external parts are thoroughly cleaned. Windings, encoders, bearings, and brake systems are tested.

- Component Replacement – Any worn or damaged components—including bearings, seals, windings, or connectors—are replaced with OEM-grade or certified equivalent parts.

- Reassembly & Calibration – The motor is reassembled, aligned, and tested for shaft runout, encoder synchronization, brake torque, and overall mechanical balance.

- Final Testing & Quality Control – The refurbished unit is tested under load conditions on a Fanuc control system to ensure it meets OEM performance standards.

Advantages of Choosing Refurbished Fanuc Motors

Refurbished Fanuc servo motors provide significant cost savings without compromising on reliability or precision. In most cases, customers save 50% to 75% So, do the math. If you replace three Fanuc parts a year and would spend $18,000 on new motors, drives, and amplifiers, then buying refurbished could realistically save your company $9,000 a year at no loss of reliability or quality. Note that the key to a good refurbishing job is good performance testing, to ensure the repaired and reassembled motor or drive really works as advertised. compared to new OEM units. Refurbished parts also:

- Match OEM performance in speed, torque, and accuracy

- Undergo rigorous quality assurance testing

- Often include warranties comparable to new parts

- Are available more quickly than factory-direct replacements

Refurbishment also aligns with sustainability initiatives by extending the lifecycle of industrial equipment and reducing electronic waste.

Signs It’s Time to Refurbish Your Servo Motor

You may not need to wait until total failure to consider refurbishment. Warning signs include:

- Inconsistent axis movement or drifting

- Overcurrent or positioning alarms on Fanuc controls

- Unusual motor noise or vibration

- Overheating under standard load

- Decreased productivity or dimensional inaccuracy

Whether you’re looking to extend the life of your CNC equipment or reduce the cost of critical part replacements, CIT is your trusted source for refurbished Fanuc motors that perform like new—at a fraction of the cost.

Contact CIT Automation Equipment today for a quote or to check availability on refurbished Fanuc servo motors and components. Let us help keep your automation systems running at peak efficiency.

Do You Know Your Part Number?

Enter part information below to check pricing and availability

Reseller or Distributer?