As with any critical industrial equipment, routine maintenance of Fanuc motors is essential to ensure optimal performance, reduce repair costs, and avoid unexpected downtime. Both Fanuc spindle motors 和 servo motors are tightly integrated into larger CNC systems, where one failing component—such as a worn encoder, faulty connector, or overheating issue—can quickly lead to poor output or full system shutdown.

This guide explores the importance of maintaining your Fanuc motors, including recommended scheduling, key checkpoints, and how partnering with trusted suppliers like CIT Automation Equipment can help you keep your operations running smoothly.

Why Preventive Maintenance Saves More Than It Costs

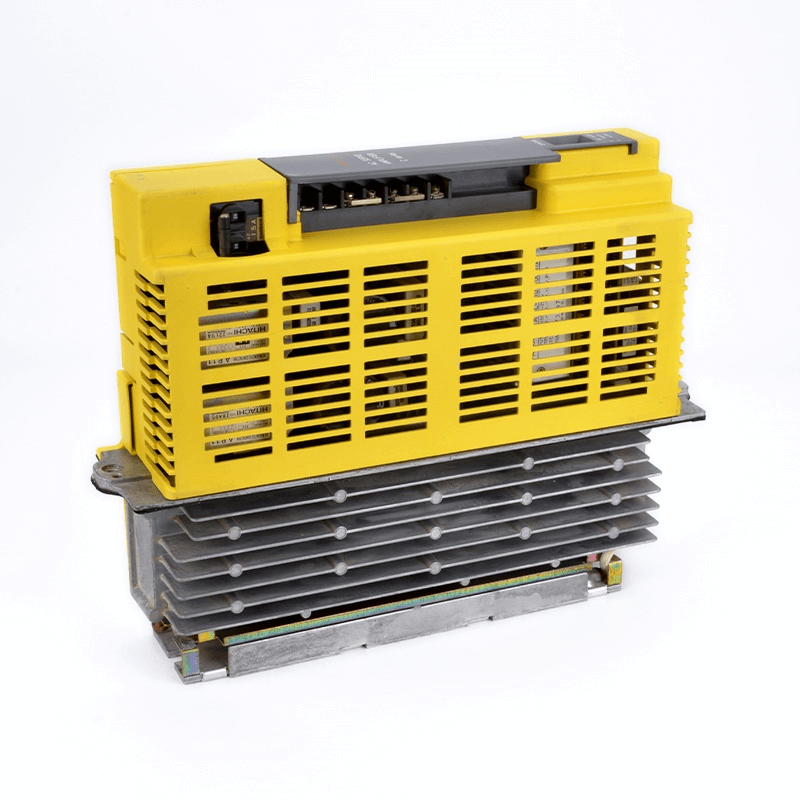

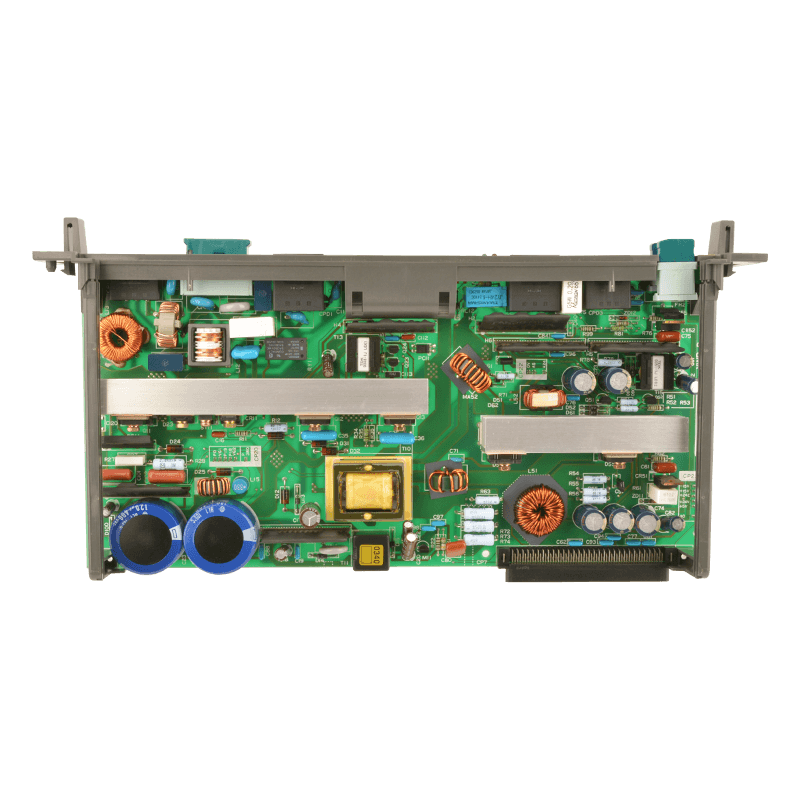

Think of your Fanuc motor as the engine of a CNC machine—just like a commercial vehicle, your router, lathe, or milling center has multiple subsystems that require attention. Regular maintenance helps extend the life of not only the motor itself but also associated parts like amplifiers, encoders, bearings, and cooling fans.

Skipping routine checks can lead to:

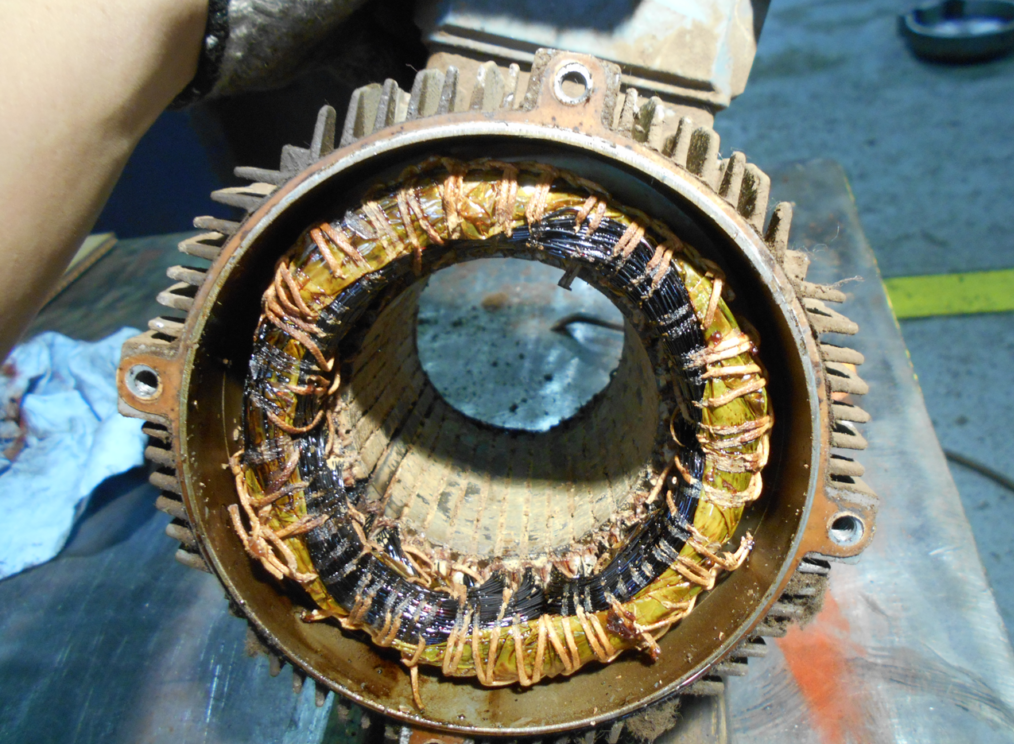

- Overheating and insulation damage

- Poor torque output or loss of precision

- Shortened motor lifespan

- Unplanned downtime that halts production

- Costly emergency repairs or replacements

Overheating

Many manufacturers follow OEM-recommended intervals, but others may benefit from creating a custom maintenance plan based on actual usage and environment. For instance, a Fanuc spindle motor running 20 hours a day in a dusty environment will need more frequent care than one operating occasionally in a cleanroom.

Fanuc Motor Maintenance Schedule: Daily to Annual Checks

Implementing a structured schedule can help detect early signs of wear or malfunction. Here’s a suggested breakdown for Fanuc motor maintenance based on industry best practices:

Daily

- Wipe down motor housings and shafts to remove dust and residue

- Check for abnormal vibration, noise, or overheating

- Monitor control panel for alarm codes or inconsistent motor output

Weekly

- Verify cooling fans and airflow channels are functioning

- Perform a visual inspection of cables, drives, and nearby components

- Clean the area around the machine to prevent buildup

Monthly (or Every 500 Hours)

- Deep clean cooling vents and fan filters

- Check lubricant levels and consumption trends

- Inspect pulleys, couplings, and belts for tension and wear

Semi-Annually (1,000 Hours)

- Inspect and clean brushes on applicable DC motors

- Test insulation resistance if your motors run in high humidity or dusty environments

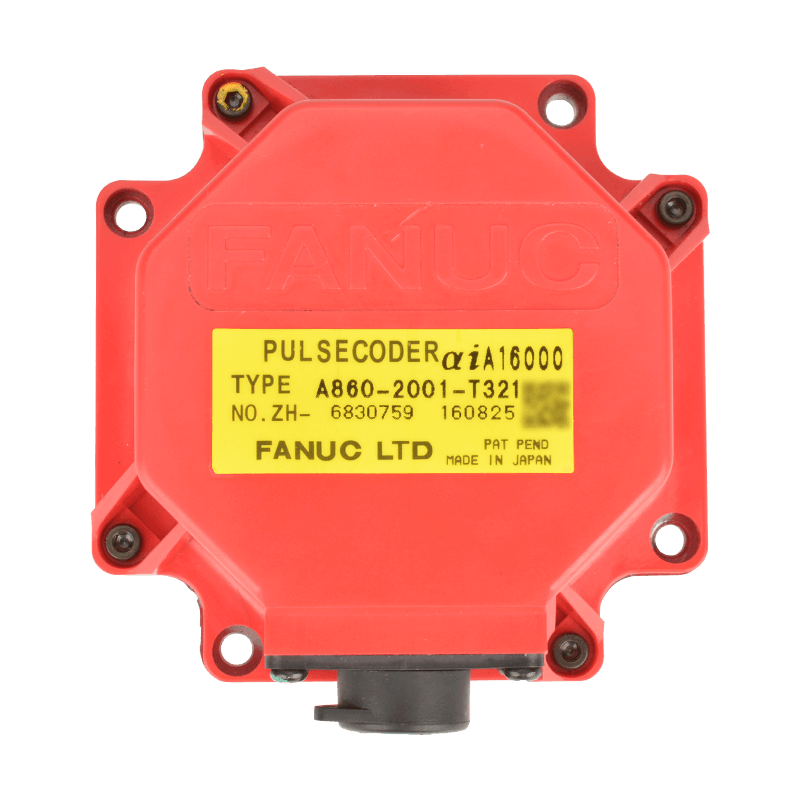

- Recalibrate feedback devices if needed

Annually (2,000+ Hours)

- Perform thermal imaging or vibration analysis to identify internal issues

- Replace air and oil filters if part of your system

- Run diagnostic tests or simulations to benchmark motor efficiency

Don’t Forget Connected Components

When maintaining Fanuc motors, don’t overlook the peripheral elements. Components such as motor sensors, signal cables, connectors, and power modules can all cause motor symptoms without the motor itself being the issue.

Pay close attention to:

- Worn or frayed signal wiring

- Loose or corroded connectors

- Gear backlash or misalignment

- Moisture or coolant infiltration

- Dirt and oil accumulation in tight areas

Cleaning the machine exterior, surrounding environment, and inside electrical cabinets should be part of your full-system maintenance routine. Keeping the shop clean is not just about hygiene—it’s about keeping your equipment operational and your output reliable.

Trust CIT Automation Equipment for Fanuc Motor Solutions

Even the best maintenance can’t prevent all issues—but having the right partner makes all the difference. Whether you’re looking for new Fanuc spare motors, expert guidance on your maintenance plan, or urgent motor repair services, CIT Automation Equipment is here to help.

We supply a wide selection of authentic Fanuc motors and replacement parts, backed by industry expertise and prompt global delivery. If your CNC system is down, our team can help you troubleshoot, repair, or source the correct motor quickly and affordably.

Stay productive. Stay prepared. Choose CIT Automation Equipment for all your Fanuc motor service and sales needs.