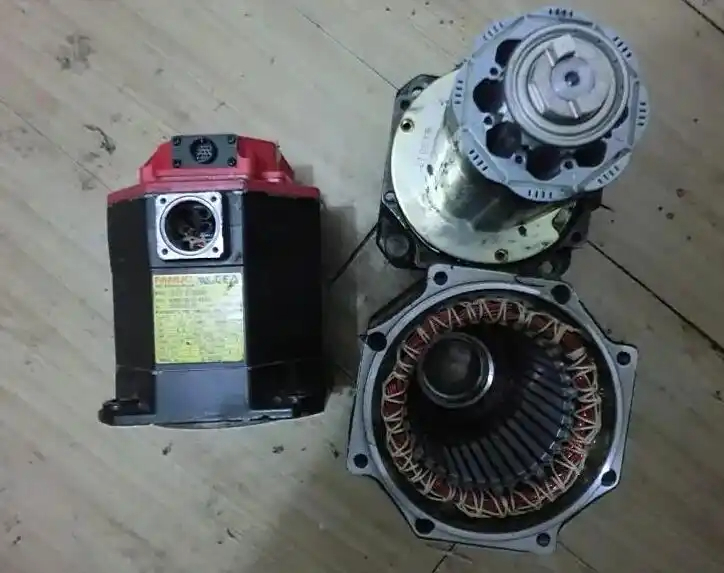

If your FANUC servo motor or spindle motor triggers alarms such as Alarm 8, Alarm 9, Alarm A, Alarm B, or Alarm 12, it often indicates electrical or motor-related faults. These errors typically point to overcurrent conditions (HC alarms), short circuits, or grounding problems.

This article outlines a step-by-step troubleshooting method to determine whether the issue lies with the FANUC motor or the servo/spindle amplifier. Proper diagnostics are crucial to avoid replacing the wrong component and incurring unnecessary downtime and costs.

Initial Diagnosis – Disconnect Motor Leads and Check Alarm LED

1.Disconnect the four power leads between the FANUC motor and the drive amplifier.

2.Power ON the CNC machine and observe the status of the HC Alarm LED on the amplifier module.

- If the HC LED (High Current) alarm disappears, the motor may be the source of the fault.

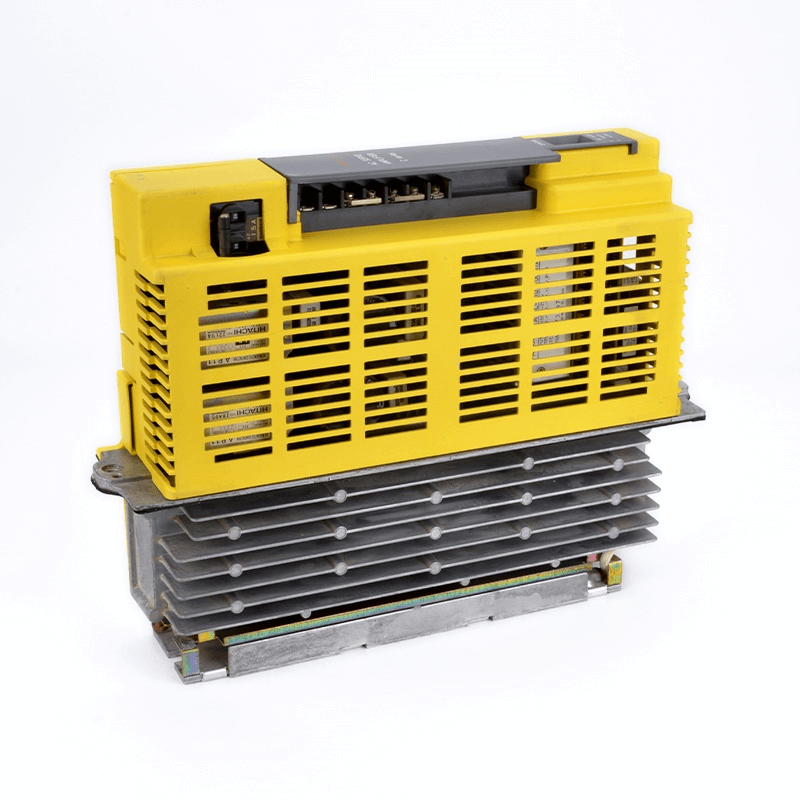

- If the HC alarm persists (e.g., Alarm 8, 9, A, B on the servo or Alarm 12 on the spindle), the drive amplifier might be faulty.

Note: For spindle amplifiers, the HC alarm may only appear after issuing a low-speed M-code command to the motor.

Alarm 8,9, A, B or 12 on Fanuc Spindle and Servo Motors

Step-by-Step Electrical Testing of FANUC Servo Motor

To further determine the cause, test the motor’s insulation and resistance using a digital multimeter and a megohmmeter.

Step 1: Resistance Test (Using Ohmmeter)

- Measure phase-to-phase (leg-to-leg) and phase-to-ground (leg-to-ground) resistance:

- All leg-to-leg readings (U-V, V-W, W-U) should be low and consistent.

- All leg-to-ground readings (U-G, V-G, W-G) should show open circuit (OL).

Any short or imbalance may indicate an internal winding issue or ground fault in the motor.

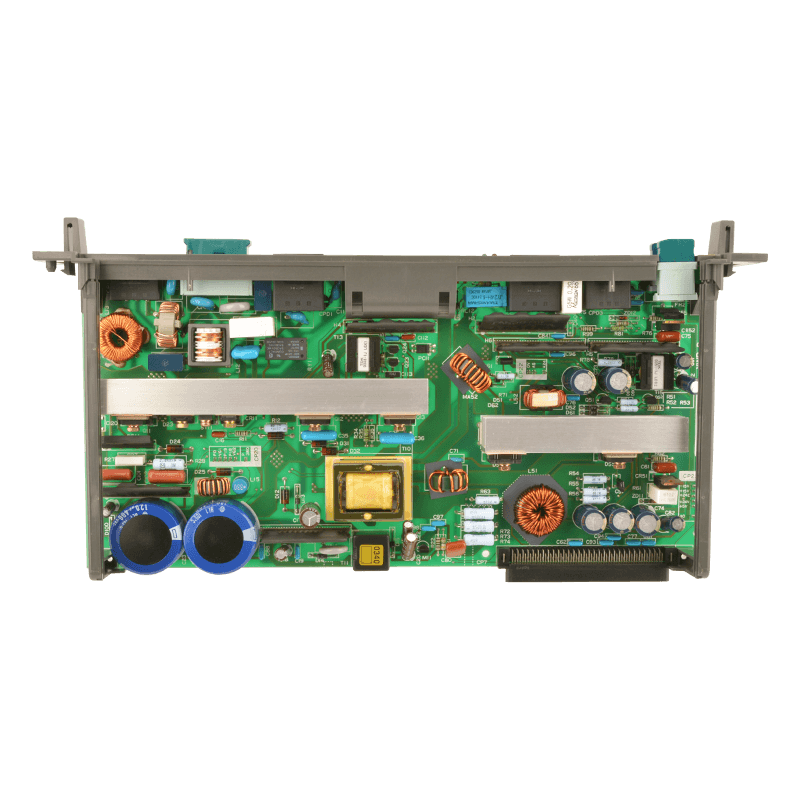

Step 2: Insulation Test (Using Megohmmeter)

- Use a megohmmeter (megger) set to 1000V and test each phase leg (U, V, W) to ground:

- The reading should be infinite (or ≥500 MΩ).

- Test from both the motor side and cable terminals, as problems can arise in the motor power connector, terminal box, or power cable from the drive.

This helps verify insulation integrity and locate moisture ingress, contamination, or cable damage.

Alarm 8,9, A, B or 12 on Fanuc Spindle and Servo Motors

What to Do Next – Motor or Drive?

- If the motor passes both tests but the HC alarm persists when disconnected, suspect a defective amplifier module.

- If the motor fails insulation or resistance tests, it’s likely damaged and should be repaired or replaced.

Whether you’re troubleshooting FANUC Alarm 8, 9, A, B, or Alarm 12, CIT can help restore your CNC system with precision and reliability.

Contact CIT Automation Equipment today for professional repair services, part replacements, or technical support.